Electrical conduit installation involves enclosing and protecting electrical wires in a structured system․ Proper planning, material selection, and adherence to safety standards ensure a reliable and code-compliant setup․

Planning and Preparation

Planning involves assessing the site, creating a detailed layout, and confirming supply voltage․ Identify isolation points and plan routes to ensure efficient and safe electrical conduit installation․

2․1 Assessing the Site

Assessing the site is crucial for a successful conduit installation․ Evaluate the environment to determine if it’s suitable for underground or exposed setups․ Check for existing infrastructure, soil conditions, and potential obstacles․ Ensure compliance with local regulations and safety standards․ Identify power sources and isolation points to plan the layout effectively․ This step helps in avoiding costly rework and ensures the system’s reliability․ Proper site assessment also aids in selecting the right materials and tools, ensuring the installation meets all necessary specifications and codes․ By thoroughly evaluating the site, you can anticipate challenges and plan accordingly, leading to a smoother installation process․ This initial assessment sets the foundation for a safe and efficient electrical conduit system․

2․2 Creating a Layout

Creating a detailed layout is essential for a well-organized electrical conduit installation․ Begin by reviewing the conduit design layout and plans to determine the optimal routes for the conduits․ Use tools like fish tape to map out the path and ensure proper wire placement․ Identify isolation points and confirm the supply voltage to maintain system compatibility․ Consider thermal expansion and contraction when routing the conduit, especially for outdoor installations․ Mark the locations for conduit bends, couplers, and boxes to ensure precise placement․ Use conduit fittings and accessories that match the layout design to maintain structural integrity․ Double-check the layout against local building codes and regulations to avoid compliance issues․ A well-planned layout ensures efficient wire routing, reduces material waste, and simplifies future maintenance․ Proper execution of the layout is critical for a safe and reliable electrical system․

Safety Guidelines and Precautions

Adhering to safety guidelines is crucial during electrical conduit installation to prevent accidents and ensure compliance with regulations․ Always wear personal protective equipment (PPE) such as gloves, safety glasses, and a hard hat․ De-energize circuits before starting work to avoid electrical shocks․ Use properly insulated tools and ensure all equipment is grounded․ Follow the IET Wiring Regulations (BS 7671) and local codes meticulously․ Avoid overloading conduits, as this can lead to overheating and fire hazards․ Secure conduits within three feet of connections to electrical boxes for stability․ Properly label all conduits to prevent accidental damage during future work․ Ensure thermal expansion and contraction are accounted for to prevent system failure․ Regularly inspect tools and materials to maintain safety standards․ If unsure about any procedure, consult a qualified professional to ensure safe and correct installation practices․ Safety must never be compromised in any phase of the installation process․

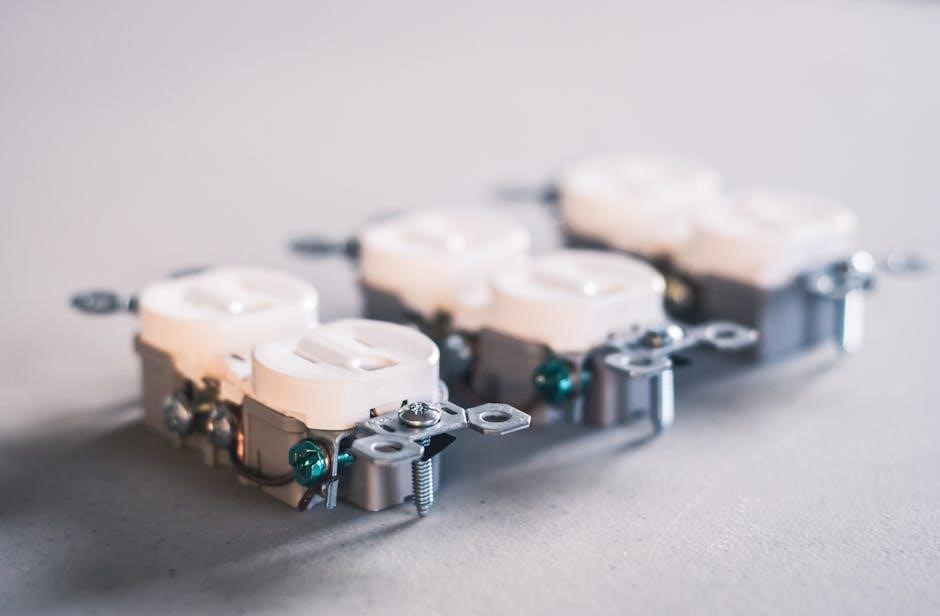

Tools and Materials Needed

Successful electrical conduit installation requires the right tools and materials․ Essential tools include a pipe cutter, drill press, hole saw, fish tape, conduit bender, and wire strippers․ Materials needed are PVC conduit pipes, fittings (elbows, couplers, tees), electrical boxes, and wire nuts․ Use high-quality PVC cement and primer for secure connections․ Ensure all items meet local electrical codes and standards․ Accessories like conduit hangers, clips, and sealants are also necessary for a durable setup․ Properly label all wires and conduits for clarity․ Always verify the compatibility of materials with the environment, such as moisture-resistant options for outdoor use․ Having the correct tools and materials on hand ensures efficiency and compliance with safety regulations․ Invest in durable equipment to handle repeated use and varying project demands․ Proper organization of these items streamlines the installation process and minimizes delays․

Step-by-Step Installation Process

Plan the route, mark locations, and prepare tools․ Use fish tape to guide wires through conduit․ Secure conduit within three feet of boxes․ Ensure compliance with local codes․

5․1 Underground Installation

Underground electrical conduit installation requires careful planning and execution to ensure durability and safety․ Begin by assessing the site for soil type, water tables, and existing utilities․ Mark the trench route and dig to the required depth, ensuring compliance with local regulations․ Lay the conduit, securing it with concrete or sand for protection․ Use PVC conduit for non-pressure applications, as it resists corrosion and environmental factors․ Properly seal all joints and connections to prevent water ingress․ After installing the conduit, refill the trench, compact the soil, and restore the surface․ Always follow safety guidelines, such as using proper trenching equipment and ensuring the system is grounded․ Regular inspections and testing are crucial to maintain the integrity of the underground installation․ Adhere to local electrical codes and best practices for a reliable and long-lasting setup․

5․2 Exposed Installation

Exposed electrical conduit installation is a common method used in industrial and commercial settings where the conduit is visible․ Begin by planning the route, ensuring it aligns with electrical codes and avoids obstacles․ Use fish tape to guide wires through the conduit system, securing it within three feet of electrical boxes․ Fasten the conduit to surfaces using clips or straps, maintaining proper spacing for thermal expansion․ Protect the system from environmental factors and ensure all connections are sealed․ Exposed installations offer ease of access for maintenance and can be aesthetically pleasing when properly organized․ Always follow local regulations and safety guidelines to ensure a secure and efficient setup․ Regular inspections are essential to maintain the integrity of the exposed conduit system․ Proper installation practices guarantee reliability and longevity, making it a practical choice for many applications․

Understanding Thermal Expansion and Contraction

Thermal expansion and contraction are critical factors in electrical conduit installation, as materials expand and contract with temperature changes․ PVC conduit, for instance, expands at a rate of 3 x 10^-5 in․/in․/°F, or about 3/8 inch per 100 feet for every 10°F temperature change․ This movement can cause stress on the system if not properly accommodated․ To manage this, installers should incorporate expansion joints or flexible couplings in long conduit runs․ Additionally, conduit should be secured firmly at regular intervals to prevent shifting due to thermal movement․ Proper planning and material selection are essential to ensure the system remains stable and functional over time․ Regular inspections can help identify potential issues caused by thermal expansion and contraction, ensuring long-term reliability and safety of the installation․

Wiring and Circuit Connections

Wiring and circuit connections are the final steps in completing an electrical conduit installation․ Once the conduit is securely in place, the electrical wires are carefully pulled through using tools like fish tape․ Proper wire management ensures that the system operates safely and efficiently․ Secure the conduit within three feet of electrical boxes to maintain stability․ Adhere to the IET Wiring Regulations (BS 7671) to ensure compliance with safety standards․ Avoid overfilling the conduit, as this can lead to damage or fire hazards․ Use appropriate connectors and junction boxes to maintain the integrity of the circuit․ Labeling wires clearly is crucial for future maintenance and troubleshooting․ Always test the circuit for continuity and voltage before energizing the system to ensure everything functions correctly and safely․

Inspections and Testing

Inspections and testing are critical final steps to ensure the electrical conduit installation meets safety and performance standards․ Begin with a visual inspection to verify that all conduits are securely fastened, properly aligned, and free from damage․ Check for any obstructions or sharp bends that could compromise wire integrity․ Perform continuity tests using a multimeter to confirm that circuits are correctly connected and functioning as intended․ Test for voltage to ensure there are no live wires where they shouldn’t be․ Conduct insulation resistance tests using a megohmmeter to identify any faults or weak points in the wiring․ Ensure all connections comply with local electrical codes and regulations․ Document the results for future reference and address any issues before energizing the system․ Proper testing ensures reliability, safety, and long-term durability of the electrical system․

Cost-Saving Tips for Installation

Implementing cost-saving strategies during electrical conduit installation can significantly reduce expenses without compromising quality․ Start by planning thoroughly to minimize material waste and labor time․ Opt for durable, long-lasting materials like PVC conduit, which offers resistance to corrosion and environmental factors, reducing future maintenance costs․ Consider pre-fabricated conduit systems to streamline the process and lower labor expenses․ Additionally, ensure proper sizing of conduits to avoid over-specifying materials․ Regularly inspect and maintain tools to extend their lifespan․ Finally, consider energy-efficient solutions and rebates offered by utility companies, which can offset initial installation costs․ By prioritizing efficiency and smart material selection, you can achieve a cost-effective and reliable electrical system․

Maintenance and Upkeep

Regular maintenance and upkeep are essential to ensure the longevity and safety of electrical conduit systems․ Start by inspecting conduits for signs of damage, wear, or environmental stress, particularly in areas exposed to harsh conditions․ Thermal expansion and contraction of PVC conduit systems should be monitored to prevent structural issues․ Clean out debris and dust from conduits periodically to maintain optimal wire protection․ Avoid overloading conduits, as this can lead to system failures․ Use high-quality materials like PVC conduit, which offers resistance to corrosion and environmental factors, reducing the need for frequent repairs․ Additionally, ensure all connections and fittings are secure to prevent electrical hazards․ Regularly scheduled maintenance can help identify and address potential issues before they escalate, ensuring a reliable and safe electrical system;

Best Practices for a Successful Installation

Adhering to best practices ensures a safe, efficient, and durable electrical conduit installation․ Begin with thorough planning and site assessment to identify potential challenges․ Use high-quality materials, such as PVC conduit, to withstand environmental factors and ensure longevity․ Always follow safety guidelines, including proper grounding and insulation, to prevent electrical hazards․ Secure conduits within three feet of connections to electrical boxes for stability․ Consider thermal expansion and contraction by allowing space for movement to avoid damage․ Employ tools like fish tape for wire placement and ensure tight connections to maintain system integrity․ Keep records of the installation for future reference and compliance checks․ Regular inspections and timely repairs can prevent major issues․ By following these practices, you achieve a reliable and code-compliant electrical system that meets safety and performance standards․

Regulatory Compliance

Ensuring regulatory compliance is crucial for a legal and safe electrical conduit installation․ Adhere to local and national electrical codes, such as the IET Wiring Regulations (BS 7671), to meet safety and performance standards․ Familiarize yourself with specific guidelines for conduit materials, sizing, and installation methods․ Always verify that materials like PVC conduit meet approved specifications for non-pressure applications․ Compliance also involves proper labeling and documentation of the system for inspections․ Consulting with local authorities and certified professionals ensures adherence to regional regulations․ Regular updates to codes and standards should be monitored to maintain compliance throughout the installation process․ By following these regulations, you ensure a safe, efficient, and legally approved electrical system that protects both people and property․