Welding is a fundamental process in manufacturing and construction‚ enabling the joining of metals and thermoplastics through heat and pressure. Essential for building structures‚ machinery‚ and vehicles‚ welding textbooks provide foundational knowledge and practical skills‚ ensuring safety and efficiency in various industries.

1.1 Basic Principles of Welding

Welding’s core principles involve joining materials through heat‚ pressure‚ or both. Fusion welding melts base metals‚ often with filler material for strength. Solid-state welding uses pressure or friction without melting. These principles form the foundation for various techniques‚ ensuring strong‚ durable joints in manufacturing and construction applications.

1.2 The Role of Welding in Modern Industry

Welding is indispensable in modern manufacturing‚ enabling the production of machinery‚ vehicles‚ and infrastructure. It supports aerospace‚ construction‚ and energy sectors by creating durable‚ precise structures. Its adaptability and reliability drive technological advancements‚ ensuring efficient and high-quality outcomes across industries‚ making it a cornerstone of industrial progress and innovation.

1.3 Why Study Welding Through Textbooks?

Textbooks provide structured‚ comprehensive learning‚ covering theory‚ safety‚ and practical techniques. They offer detailed explanations‚ diagrams‚ and real-world applications‚ ensuring a strong foundation in welding. Accessible in PDF‚ textbooks are invaluable resources for students and professionals‚ supporting continuous learning and skill development in this essential trade.

Types of Welding Processes

Welding processes include fusion‚ arc‚ gas‚ and solid-state methods‚ each with unique techniques and applications‚ ensuring versatility in joining materials efficiently and effectively across industries.

2.1 Fusion Welding Processes

Fusion welding processes involve melting the base metals to create a strong joint‚ often with filler material. Techniques include arc‚ MIG‚ TIG‚ and laser welding‚ each offering distinct advantages in precision‚ speed‚ and adaptability for various materials and industrial applications.

2.2 Arc Welding and Its Variants

Arc welding uses an electric arc to melt and join metals. Variants include Shielded Metal Arc Welding (SMAW)‚ Gas Metal Arc Welding (GMAW or MIG)‚ Flux Cored Arc Welding (FCAW)‚ and Submerged Arc Welding (SAW). Each method offers unique advantages‚ such as portability‚ speed‚ or precision‚ catering to diverse industrial and fabrication needs.

2.3 MIG‚ TIG‚ and Other Gas Welding Techniques

MIG (GMAW) welding uses a continuous wire electrode for high-speed‚ versatile joining of metals. TIG (GTAW) welding employs a non-consumable tungsten electrode for precise‚ high-quality welds‚ often in stainless steel and aluminum. Other gas techniques include MAG welding and plasma welding‚ each offering distinct advantages in specific industrial applications and materials.

2.4 Solid-State Welding Methods

Solid-state welding joins materials without melting‚ using mechanical or thermal energy. Techniques like friction stir welding and explosion welding create strong bonds through deformation or impact. These methods are ideal for materials that degrade when melted‚ offering high integrity and minimal distortion in applications like aerospace and automotive industries.

Safety Guidelines and Best Practices

Proper safety gear‚ including helmets and gloves‚ is essential. Ensure good ventilation to avoid fume inhalation. Regularly inspect equipment and follow established protocols to prevent accidents and injuries.

3.1 Essential Safety Equipment for Welders

Welding helmets with face shields and auto-darkening lenses protect eyes and skin from UV rays and sparks. Heat-resistant gloves prevent burns‚ while safety glasses with UV protection ensure eye safety. Fire-resistant clothing and closed-toe shoes minimize fire hazards. Proper ventilation systems are crucial to avoid inhaling harmful fumes during welding processes.

3.2 Hazard Prevention in Welding Environments

Prevent fires by removing flammable materials and ensuring proper ventilation. Regularly inspect equipment to avoid gas leaks and electrical malfunctions. Use fire-resistant curtains or screens to contain sparks. Implement no-smoking policies in welding areas and train workers on emergency procedures to mitigate risks effectively.

3.3 Emergency Procedures in Welding Accidents

In case of welding accidents‚ immediately turn off equipment and evacuate the area. For burns‚ cool the affected area with water and seek medical help. Fire extinguishers should be readily available to control flames. Ensure first aid kits are accessible‚ and train personnel in CPR and emergency response to handle incidents effectively.

Welding Textbooks and Educational Resources

Popular welding textbooks‚ such as the AWS Handbook‚ offer comprehensive guides on techniques‚ safety‚ and materials. Free PDF downloads provide accessible learning for students and professionals.

4.1 Popular Welding Textbooks Available in PDF

Popular welding textbooks‚ such as the AWS Welding Handbook and “Welding: Principles and Applications‚” are widely available in PDF format. These resources cover essential topics like fusion welding‚ arc welding‚ and metal fabrication‚ providing both theoretical and practical knowledge for students and professionals. Free downloads offer accessible learning for skill development.

4.2 Guide to Downloading Free Welding Manuals

To access free welding manuals‚ visit reputable websites like the American Welding Society or academic platforms offering PDF downloads. Use search terms like “free welding textbook PDF” or “download welding manuals.” Verify the source’s credibility and ensure the content aligns with your learning needs for safety and accuracy.

4.3 How to Choose the Right Welding Textbook

Selecting the right welding textbook involves considering your skill level‚ learning objectives‚ and the specific welding processes covered. Look for books that include practical exercises‚ clear illustrations‚ and updated safety guidelines. Prioritize textbooks from reputable publishers‚ such as the AWS Welding Handbook‚ to ensure accuracy and comprehensive coverage of welding techniques.

The AWS Welding Handbook

The AWS Welding Handbook is a comprehensive guide covering welding science‚ technology‚ and applications. It serves as an essential resource for professionals and students‚ offering detailed insights into various welding processes and best practices.

5.1 Overview of the AWS Welding Handbook

The AWS Welding Handbook is a primary reference for welding professionals and students‚ offering comprehensive coverage of welding science‚ technology‚ and applications. It details materials‚ processes‚ and best practices‚ serving as an essential guide for both educational and industrial purposes.

5.2 Key Topics Covered in the Handbook

The AWS Welding Handbook covers fundamental topics such as fusion welding processes‚ arc and gas welding techniques‚ and safety protocols. It also includes detailed sections on metal weldability‚ brazing‚ soldering‚ and quality control‚ providing a robust foundation for both theoretical understanding and practical application in welding.

5.3 Benefits of Using the AWS Welding Handbook

The AWS Welding Handbook offers comprehensive insights into welding science and technology‚ providing updated techniques and standards. It serves as a valuable resource for both professionals and learners‚ enhancing theoretical and practical knowledge while ensuring adherence to industry best practices and safety guidelines.

Welding Fabrication and Metal Joining

Welding fabrication involves shaping and assembling metal parts through cutting‚ bending‚ and joining techniques. It is essential for creating structures‚ machinery‚ and other metal products‚ ensuring durability and precision in various industries.

6.1 Basics of Metal Fabrication

Metal fabrication involves cutting‚ bending‚ and assembling metal components. Techniques include shearing‚ punching‚ and welding. Proper tools and safety measures ensure precision and durability. Welding textbooks detail these processes‚ helping fabricators master skills for creating robust structures and machinery‚ essential in manufacturing and construction‚ ensuring quality and efficiency in every project.

6.2 Advanced Techniques in Metal Joining

Advanced techniques like laser beam welding and friction stir welding offer precision and strength. These methods minimize distortion and improve joint integrity. Robotic automation enhances efficiency‚ while specialized tools optimize results. Welding textbooks detail these processes‚ ensuring fabricators can apply cutting-edge methods for high-performance applications in aerospace‚ automotive‚ and industrial sectors.

6.3 Quality Control in Welding Fabrication

Quality control in welding ensures durability and safety. Techniques like ultrasonic testing‚ radiography‚ and visual inspection detect flaws. Adherence to industry standards and proper documentation are crucial. Welding textbooks detail these methods‚ ensuring high-quality outcomes in fabrication processes.

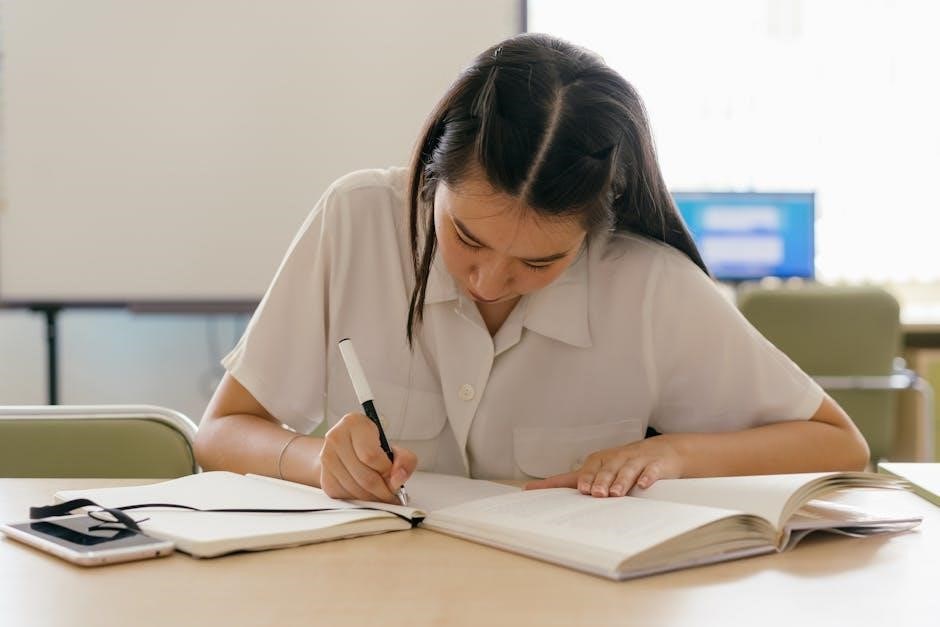

Welding Techniques for Beginners

Mastering basic welding techniques is essential for beginners. Start with proper equipment setup‚ safety practices‚ and understanding metal properties. Practice simple joints and gradually progress to complex processes for skill development.

7.1 Starting with Basic Welding Skills

Beginners should start by understanding safety protocols and equipment setup. Practice basic joints like butt and lap welds. Focus on maintaining consistent heat‚ proper electrode angles‚ and steady movement. Textbooks often provide step-by-step guides to help novices build confidence and precision in their welding techniques from the very beginning.

7.2 Common Mistakes to Avoid for Beginners

Beginners often overlook proper safety equipment and ventilation‚ leading to health risks. Incorrect electrode angles‚ insufficient heat settings‚ and poor joint alignment are frequent errors. Inconsistent welding speed and lack of practice also hinder progress. Textbooks emphasize avoiding these mistakes to ensure quality welds and safety in the learning process.

7.3 Practice Exercises for Skill Improvement

Consistent practice is essential for mastering welding techniques. Start with basic exercises like straight bead welding and corner joints. Gradually progress to fillet welds and butt joints‚ ensuring proper penetration and alignment. Practice on various materials‚ such as steel and aluminum‚ to build versatility and confidence in different welding scenarios.

Robotic and Automated Welding

Robotic welding employs advanced technologies for precision and consistency‚ minimizing human intervention. Automated systems enhance efficiency‚ safety‚ and scalability in industrial applications‚ revolutionizing modern manufacturing processes.

Robotic welding systems utilize programmable robots equipped with welding tools‚ enabling precise and consistent joining of materials. These systems are widely used in automotive and aerospace industries for high-volume production‚ offering superior accuracy and efficiency compared to manual welding methods.

By integrating advanced software and sensors‚ robotic welding ensures minimal errors and faster production cycles‚ making it a cornerstone of modern manufacturing and automation.

8.2 Advantages of Automation in Welding

Automation in welding offers enhanced speed‚ consistency‚ and scalability‚ reducing human error and improving precision. Advanced software and sensors enable high-volume production with minimal downtime‚ making it ideal for industries requiring repetitive tasks. Automated systems ensure reliability and efficiency‚ driving productivity in manufacturing sectors.

8.3 The Future of Robotic Welding Technology

Robotic welding is advancing rapidly with AI integration‚ machine learning‚ and IoT connectivity. Future systems will feature enhanced precision‚ real-time data processing‚ and adaptive learning capabilities. Collaborative robots (cobots) will work alongside humans‚ optimizing efficiency and safety. These innovations will revolutionize manufacturing‚ enabling smarter‚ faster‚ and more sustainable welding processes globally.

This concludes our exploration of welding essentials. Continuous learning through advanced resources and practice is crucial for mastering welding techniques and staying updated with industry advancements.

9.1 Summarizing Key Welding Concepts

Welding textbook PDFs emphasize safety‚ process understanding‚ and metallurgical principles. They cover fusion‚ arc‚ and gas welding‚ ensuring a strong foundation for practical applications and theoretical knowledge‚ essential for both beginners and advanced learners in the field of welding technology.

9.2 Resources for Advanced Welding Knowledge

Advanced welding knowledge can be explored through detailed textbooks and handbooks like the AWS Welding Handbook‚ offering in-depth insights into specialized techniques‚ metallurgy‚ and industrial applications. These resources are ideal for professionals seeking to enhance their expertise in modern and complex welding methodologies.

9.3 Encouragement for Continuous Learning

Embrace lifelong learning to master welding techniques and stay updated with industry advancements. Explore specialized textbooks and online resources to deepen your knowledge. Continuous learning enhances problem-solving skills‚ fosters innovation‚ and opens doors to career growth in this dynamic and evolving field.